Bubbling Fluidised Beds

The Bubbling Fluidised Beds (BFBs) are perfect for wetter or waste derived fuels up to 65% moisture content

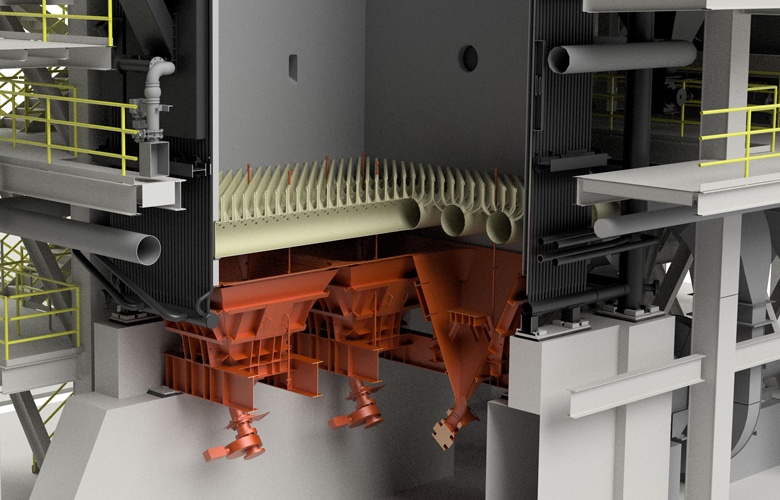

Bubbling fluidised beds burn solid fuels in an air-suspended mass (or bed) of sand.

The fluidising process is created by an upward flow of gas (air) through a bed of sand. At high enough gas velocities, the gas/solid mass exhibits liquid-like properties thus the term fluidised bed.

The fluidising gas is air, and doubles as combustion air. The combustion air is supplied via large header pipes which are each fitted with a series of bubble cap nozzles.

The bottom of the sand bed enclosure is shaped as an inverted pyramid. Only sand above the bubble caps will be fluidised once the combustion air is supplied to header pipes.

Large combustible materials will ‘float’ on the bed while burning. Any large non-combustible materials (e.g. rocks and agglomeration) pass down through the fluidised bed into the non-fluidised zone, and eventually exit with the intermittent sand drained from the bed.

Crucial to proper operation of the fluid bed is close control of the bed temperature which operates around 800°C.

Windsor’s Bubbling Fluidised Beds are designed in house under license of Babcock & Wilcox.