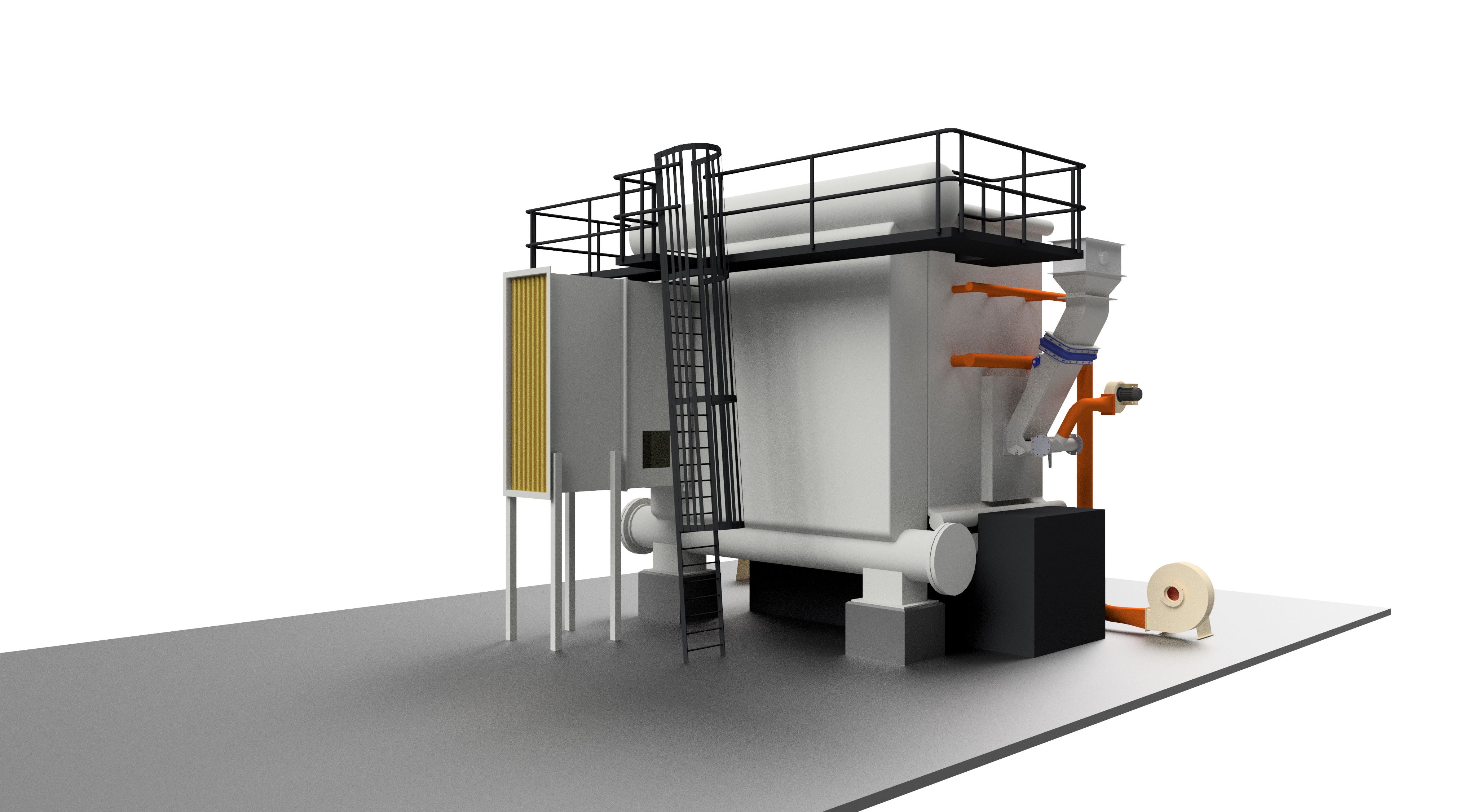

High performance, long life and low maintenance combustion systems in an affordable package

Steampac™ Biomass Boiler Range

Features

- Superior combustion system in an affordable “off the shelf” package

- Fully unattended operation in accordance with the NZ Code of Practice

- Guaranteed to meet or exceed all NZ requirements and inspections

- Up to 10bar steam

- Turndown ratio of 4:1

- Suitable for outdoor installation

- Compact combustion system for small footprint

- Valves, instruments, minor fans and motors are from global brands with local representatives, making spares and support readily accessible

- Pressure parts will be fabricated by our long-standing partner in their Thailand workshop. All other fabricated components will be fabricated in New Zealand

- Optional LPG ignition burner can start the boiler at the push of a button– can be retrofitted

- The Wood Boiler has a fully automated de-ashing system. The pellet boiler capitalises on the low ash content of wood pellets meaning only periodic manual de-ashing is required

- Balance of Plant is optional including feedtank, blowdown tank, ESP, Stack

Benefits

- Clients may save money by undertaking on site works themselves, with support from Windsor

- Minimal operator time, freeing up time for other site duties

- Minimum fuel costs achieved through high combustion efficiency

- High availability. The plant is capable of operating 24/7 between statutory inspections

- Windsor has over 20 years’ experience burning NZ wood fuels. The wood boiler can handle a wide range of ash and moisture content. It can burn sawdust, shavings and a proportion of the fuel can be sludge. It can also burn hogged fuel provided maximum length < 150mm.

- Quality product designed and supported in New Zealand including servicing and spare parts through our nationwide Service and Products divisions

- Full waterwalls make for a low refractory boiler (only minimal amount on firing wall) means low maintenance and suited to New Zealand’s seismic environment

- Windsor is the OEM of major components including our signature combustion system, pressure parts, heavy duty fans, and ducts

- Emissions will be <50mg/Nm3 achieved with optional Electrostatic Precipitator (ESP). Lower particulate levels can be achieved by a Windsor baghouse, if required

Windsor Economiser

The economiser pre-heats the boiler feedwater before it enters the steam drum. The Windsor economiser is a continuous horizontal flow design. It is designed to be non-steaming under all load conditions. Windsors in depth understanding of boiler design means we can optimise efficiency vs capital cost to provide fuel savings over time.

Water Coil Air Heater (WCAH)

Further gains in fuel efficiency and combustion stability are made using a heat exchanger in the feedwater loop to preheat the forced draft combustion air supplied to the boiler below the grate. Clients enjoy lower fuel cost, better steam control and lower particulate emissions when combustion is controlled properly. This is not required for the pellet boiler due to its low moisture content and is not included.

Control System

The control system will utilise an Allen Bradley CompactLogix based PLC and associated I/O. The human interface for the boiler is a Schneider Magelis 10.4” HMI touch screen located adjacent to the boiler. A data register is available for interfacing with the client’s site SCADA system if required. An ethernet switch is included in the panel for this purpose. The boiler control system will fully control the boiler from after manual light-off phase through to full operation of the boiler at required load. The control system will protect the integrity of the boiler from damage and fully comply with the New Zealand Boiler Code of Practice.

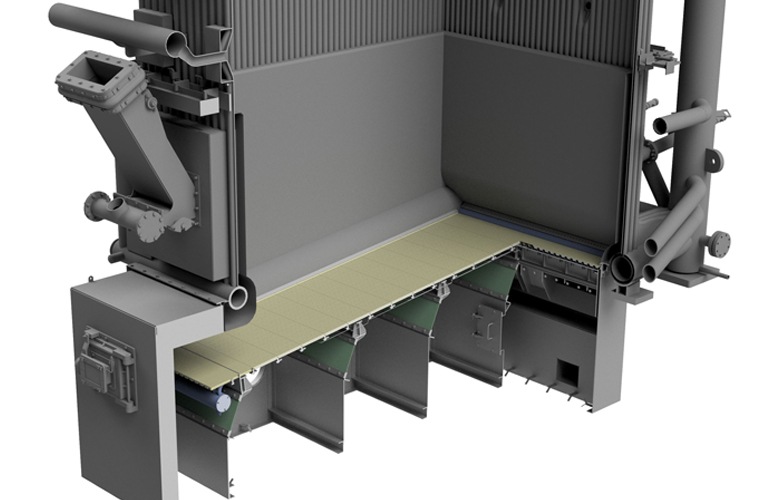

Grate Ash Extraction (Wood Boiler only)

Two ash screws from the generating bank lead into the grate ash transfer conveyor fitted at the end of the vibrating grate. These are electrically driven but could be manually operated for cost reduction purpose. The system is designed to provide continuous operation without shut-down to de-ash between statutory inspections. Due to the low ash content of pellets, manual ash extraction is sufficient.